Layout Sheet Metal - In addition to increasing material stiffness locally,. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. Cut relief between external features. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Design for minimal material displacement.

Cut relief between external features. In addition to increasing material stiffness locally,. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Design for minimal material displacement.

Cut relief between external features. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. In addition to increasing material stiffness locally,. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Design for minimal material displacement. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself.

Sheet Metal Design For Practice at Waldo Alline blog

In addition to increasing material stiffness locally,. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal hems are features where the edge of a sheet metal part is folded.

Manual Sheet Metal Layout Lesson! YouTube

Design for minimal material displacement. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal hems are features where the edge of a sheet metal part is folded back onto.

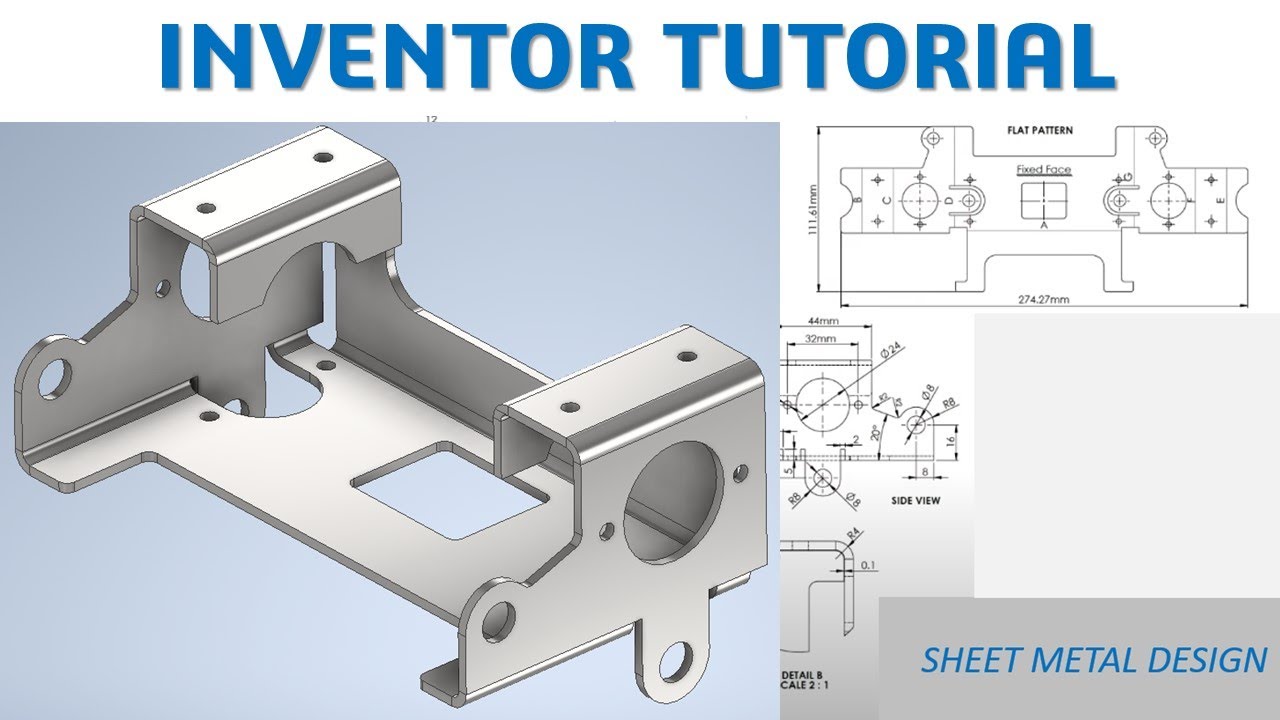

Inventor 2022 Tutorial 230 3D Sheet Metal Design YouTube

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Cut relief between external features. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production.

Sheet Metal Flat Layout Calculation YouTube

Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally,. Design for minimal material displacement. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. Cut relief between external features.

Sheet Metal Design Considerations at Freda Robert blog

Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. Design for minimal material displacement. Cut relief between external features. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal hems are features where the edge of a sheet metal.

Sheet metal part drawings for fabrication Upwork

In addition to increasing material stiffness locally,. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Design for minimal material displacement. Cut relief between external features. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors.

Sheet Metal Designing ConceptIn Detail YouTube

Design for minimal material displacement. In addition to increasing material stiffness locally,. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Learn key rules and tips for better sheet metal design that.

Solidworks Tutorial 172 Sheet Metal Tutorial Sheet Metal Design by

Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Learn key rules and tips for better sheet metal design that saves time, reduces cost, and avoids production errors. In addition to increasing material stiffness locally,. Cut relief between external features. Sheet metal fabrication is the process of forming parts from a.

SolidWorks Sheet metal Tutorial Switch Box YouTube

Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. In addition to increasing material stiffness locally,. Cut relief between external features. Design for minimal material displacement.

Sheet metal Layout And Design by Evan Collier at

Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Design for minimal material displacement. Cut relief between external features. In addition to increasing material stiffness locally,.

Learn Key Rules And Tips For Better Sheet Metal Design That Saves Time, Reduces Cost, And Avoids Production Errors.

In addition to increasing material stiffness locally,. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. Cut relief between external features.